Choose the right equipment for your needs

Eurosensors, with its subject matter experts, is the ideal choice for all your thermocouple needs. We are proud to offer a complete line of high quality products designed to ensure the precision and accuracy of your temperature measurements.

With over 10 years of experience, our team is always ready to help you find the ideal solution for your specific needs. Trust our professionalism to provide you with the best products and services for your business.

What is the role of a thermocouple?

A thermocouple is a measuring device consisting of two metal wires of different materials welded together at one end. As the temperature of the welded end increases, the difference between the two wires increases proportionally.

It is used, among other things, in high-temperature or high-pressure environments, such as gas heaters, air-conditioning and refrigeration systems, and industrial temperature measuring devices.

Our thermocouples

Types R S B

Pt13%Rh-Pt Pt10%Rh-Pt Pt30%Rh-Pt6%Rh

0 °C / +1600 °C 0 °C / +1250 °C 0 °C / +1700 °C

Whatever your need, we have the solution

For large volumes

Ask for a personalized quote

For small volumes

Buy your parts on our website Heklas.com

For expert advice

Be accompanied before making a purchase

For questions

Get advice before you order

How is a thermocouple probe used?

It is important to check that the thermocouple is suitable and that the temperature range covers the range to be measured.

The type of thermocouple must be suitable for the conditions of the application (pressure, medium, etc.) and you will also need a temperature measuring device that will convert the information into degrees (°C or °F).

What types of thermocouples to choose?

Thermocouples are adapted to specific applications depending on the temperature range to be measured, the accuracy required and the environment in which they will be used. They are differentiated by letters (Type K, J, N, T, E, etc…) which correspond to the presence of materials that can measure a certain temperature range. The most commonly used is the Type K which is capable of measuring temperatures from -40 to +1200 °C. It is made from a chrome wire and an aluminum wire.

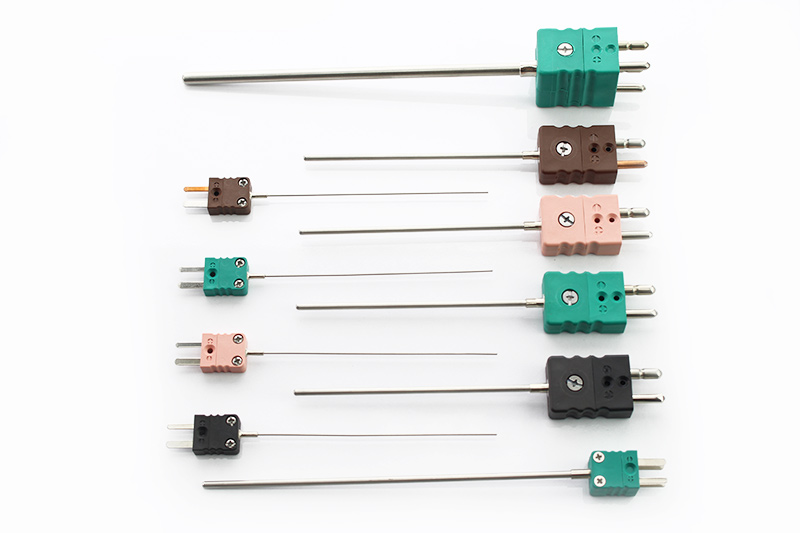

Wired or jacketed thermocouple?

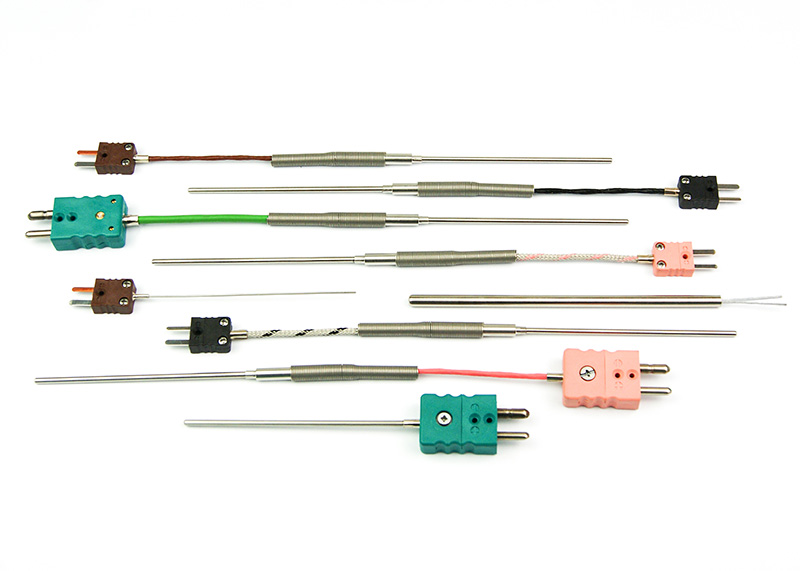

Mineral-insulated thermocouples (MIC) are temperature sensors with specific characteristics due to their metal coating. Some of the common features of jacketed thermocouples are as follows:

Environmental resistance: the metallic coating protects the wires from mechanical damage, corrosion and contamination. This allows these sensors to operate in harsh environments and to withstand a variety of external factors that could damage the wired thermocouples.

High temperatures: jacketed thermocouples can operate at higher temperatures than wire thermocouples.

Durability: Because of their protective coating, jacketed thermocouples are generally more durable and have a longer life than wire thermocouples.

Cost: Lined thermocouples are generally more expensive than wire thermocouples because they require a more complex manufacturing process to create their protective coating.

What are the characteristics of the wire thermocouple?

Wire thermocouples are simple and inexpensive temperature sensors. Some of the common features of wire thermocouples include:

Simplicity: wire thermocouples are very simple temperature sensors made of bare metal wires that are soldered together at one end.

Low cost: wire thermocouples are generally less expensive to manufacture than jacketed thermocouples because of their simple design.

Accuracy: Wire thermocouples are generally more accurate than jacketed thermocouples because they do not have a protective coating that could affect their accuracy.

Flexibility: Wire thermocouples are more flexible than jacketed thermocouples, making them easier to install in confined spaces or in hard-to-reach positions.

Fragility: wire thermocouples are more fragile than jacketed thermocouples and can be damaged by mechanical impacts, high temperatures and chemical agents.

Characteristics of the jacketed thermocouple ?

Environmental resistance: the metallic coating protects the wires from mechanical damage, corrosion and contamination. This allows these sensors to operate in harsh environments and to withstand a variety of external factors that could damage the wired thermocouples.

High temperatures: jacketed thermocouples can operate at higher temperatures than wire thermocouples.

Durability: Because of their protective coating, jacketed thermocouples are generally more durable and have a longer life than wire thermocouples.

Cost: Lined thermocouples are generally more expensive than wire thermocouples because they require a more complex manufacturing process to create their protective coating.

For which fields of application

Our thermocouples are used in many industries to measure the temperature of gases, liquids and solids in very demanding environments. Here are some examples of industries that use thermocouples:

Aeronautics/space

Agri-food

Automotive

Medical

HVAC

Why choose EuroSensors?

European manufacturing

ISO 9001 certification

Manufacturer since 2010

Warranty and service

Expert advice

More than 240 customers in over 10 countries

A project ? A quote?

We will respond as soon as possible